- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

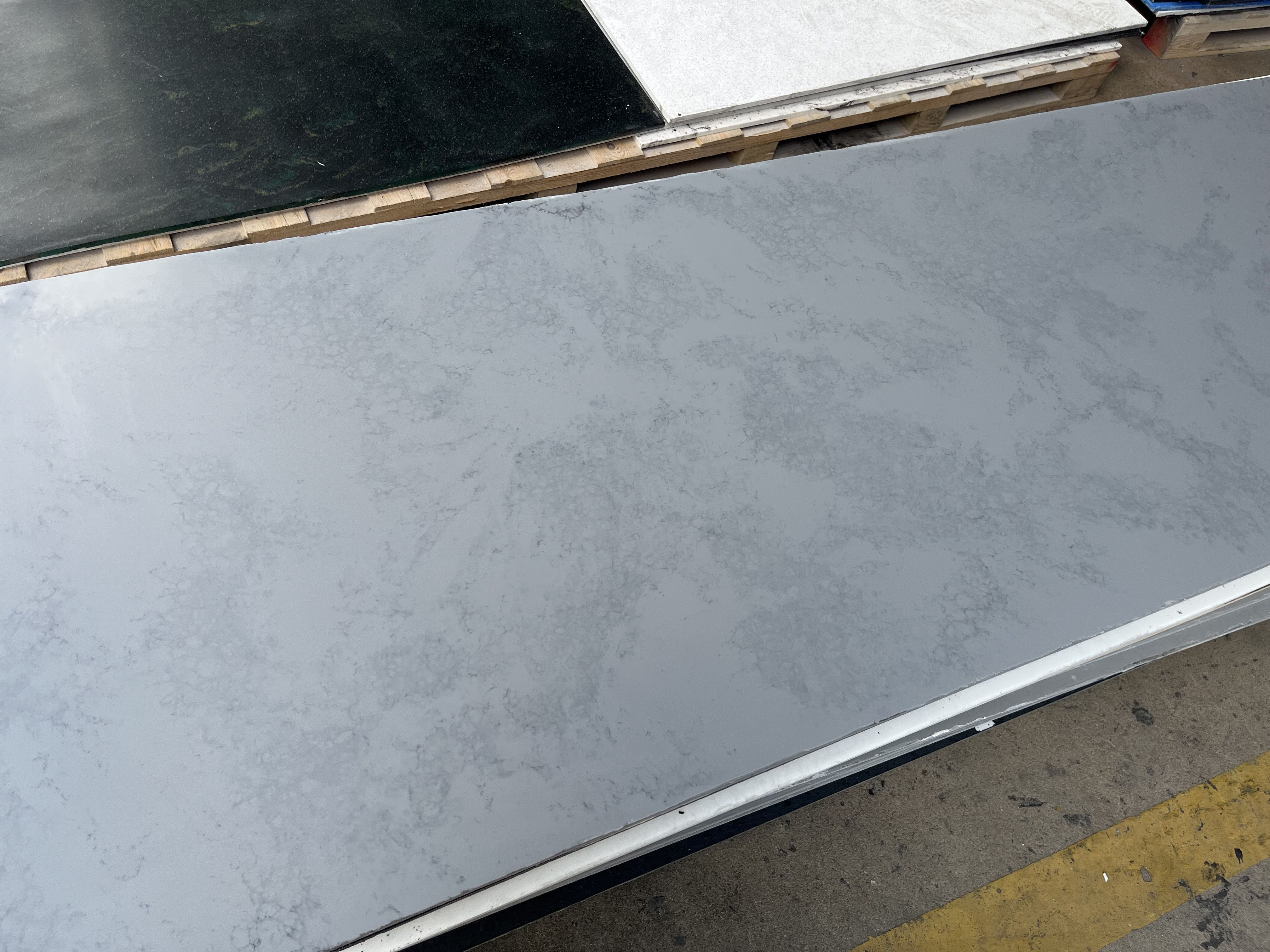

Koris New Color Arrival :

If there's any color you are interested, pls leave comments or send inquiry to me.

Advantages and Disadvantages of Artificial Stone Countertops and Classification (Part 1) Advantages: Excellent Workability: In terms of aesthetics, artificial stone is unmatched for kitchen and bathroom countertops. Its ability to be bonded seamlessly in the same material and color, creating a virtually integrated surface, is a feature that materials like natural marble and quartz stone cannot achieve

The practicality of anti-penetration: Artificial stone, also known as polymer material, possesses corrosion-resistant and anti-penetration properties, making it particularly suitable for kitchen cabinet countertops. Its popularity is well-founded (precisely addressing the shortcomings of natural marble).

No Radiation Concern: Compared to natural marble and artificial stone, it is non-radioactive and has no adverse effects on human health.

Vivid and rich hues: The palette is abundant and diverse, offering ample options for designers to mix and match, catering to individual preferences.

(2) Disadvantages:

Lack of resistance to scratching: Artificial stone of any material, with a Rockwell hardness between 58 and 62, cannot withstand scratches from sharp objects such as metals. (Resurfacing and polishing can be used for remediation.)

(3) Types of Artificial Stone:

Acrylic artificial stone

Acrylic artificial stone is a type of artificial stone with polymethyl methacrylate (PMMA) as the matrix and ultrafine aluminum hydroxide as the filler. Due to PMMA being a flowable resin, the molding process is complex and challenging. The domestically produced acrylic panels do not contain unsaturated polyester or other resins, hence the term "acrylic stone." This material boasts higher hardness, better toughness, and the ability to undergo bending processing. Additionally, it exhibits excellent weather resistance and mechanical properties, preventing natural cracking under significant temperature variations.

Composite Acrylic Artificial Stone

The composite acrylic artificial stone is produced by combining high-quality unsaturated resin with MMA for modification, using ultrafine aluminum hydroxide as the filler. The aluminum hydroxide filler is poured under vacuum, resulting in a stone with excellent toughness that can withstand significant temperature fluctuations without cracking.

Aluminum powder polyester artificial stone

The artificial stone, commonly known as aluminum powder board, is made by filling aluminum hydroxide (ATH) with unsaturated polyester resin as the binder and polymerizing it. It is environmentally friendly, non-toxic, and radiation-free, featuring excellent machinability, mechanical properties, oil resistance, and crack resistance.

Calcium powder polyester artificial stone

Low-grade artificial stone, commonly known as calcium powder board, is made by combining ordinary industrial resin with calcium carbonate powder. Since the calcium powder is a mineral powder, it may contain radioactive elements. The material has poor processing performance, prone to edge and corner chipping, inferior mechanical properties, and is brittle. Finished products are susceptible to cracking, have a short lifespan, poor resistance to pollution, easily absorb water and oil stains leading to discoloration, and are flammable without fire resistance.

(4) Processing methods and skills determine value

Various types of artificial stone slabs are merely "raw materials." To become kitchen countertops, they must undergo a process of processing and deformation. Therefore, no matter how high-quality the slabs are, without the necessary skills and targeted processing techniques to prevent expansion, they ultimately cannot achieve the desired "aesthetic and practical" kitchen countertops. Processing technology is a crucial factor in determining cost-effectiveness, with significant differences in both aesthetic and functional performance.

content is empty!